Wall Formwork

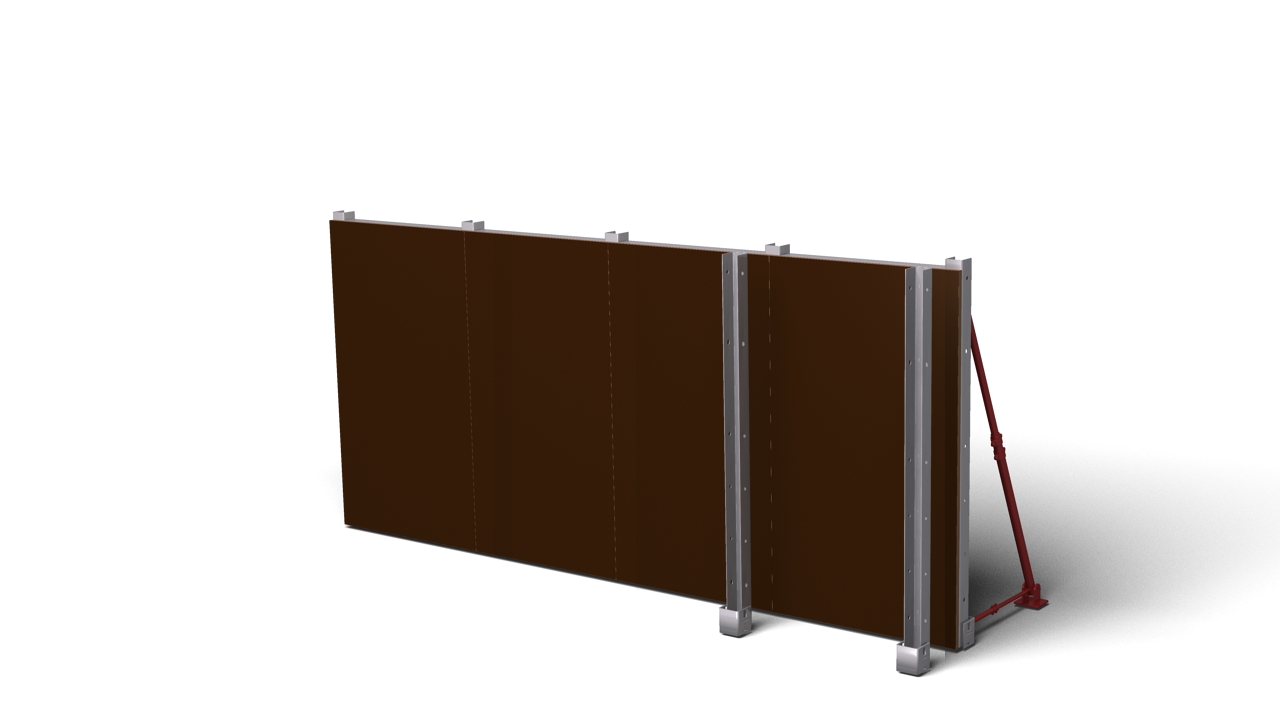

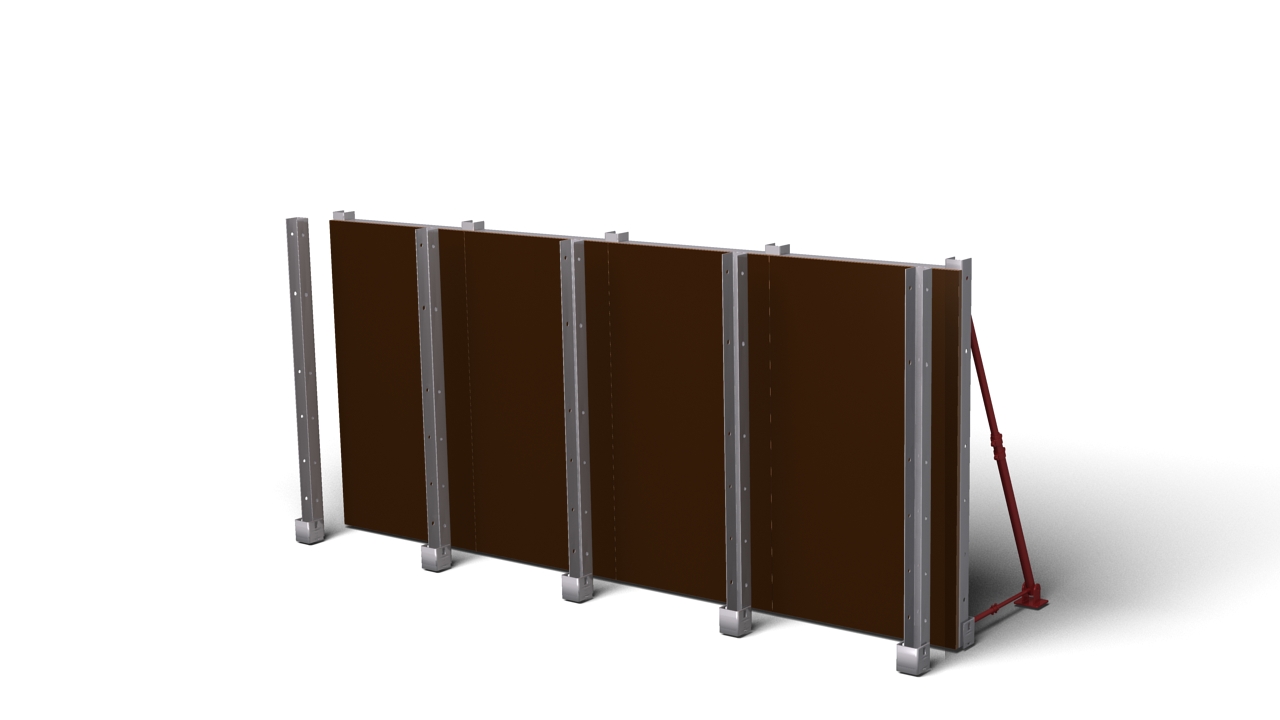

Fast-Form is the perfect solution for all types of wall formwork and column formwork. Our unique patented design offers all the strength of a steel system with the flexibility and ease of use of a hand-fit system (with the option to lift in wall panels as well). It has the finish of a traditional timber system, fewer tie bars and no panel joints, plus the same system components can form straight and radius walls! No other system offers such flexibility, but if you prefer traditional soldier and beam large formwork systems we also offer those products as well.

Wall formwork systems are easily attached and do not require a scaffolder to erect them, helping to save you time and money. Not only is timber usage reduced with our wall formwork, it is completely eliminated with the fully recyclable materials that make up the system. It is the lowest carbon and greenest wall formwork product on the market. We even provide all our customers with a carbon saving certificate so you can see exactly how much you are helping the environment with your formwork purchase.

Get in touch with our expert team today to find out more about our wall formwork. With a 25 year lifespan, you will wish you had chosen the Fast-Form formwork system sooner! Free design service included within our wall formwork calculations, just contact us today to get started.

Wall Formwork benefits

Faster

- The Fast-Form™ wall formwork system is faster than traditional timber formwork and a cost effective alternative to timber formwork systems. The Fast-Form™ formwork system is unique and has many varied uses, including column formwork as well as radius wall formwork

- The Fast-Form™ system will save you days or weeks on your program and thousands of pounds in plant or crane hire

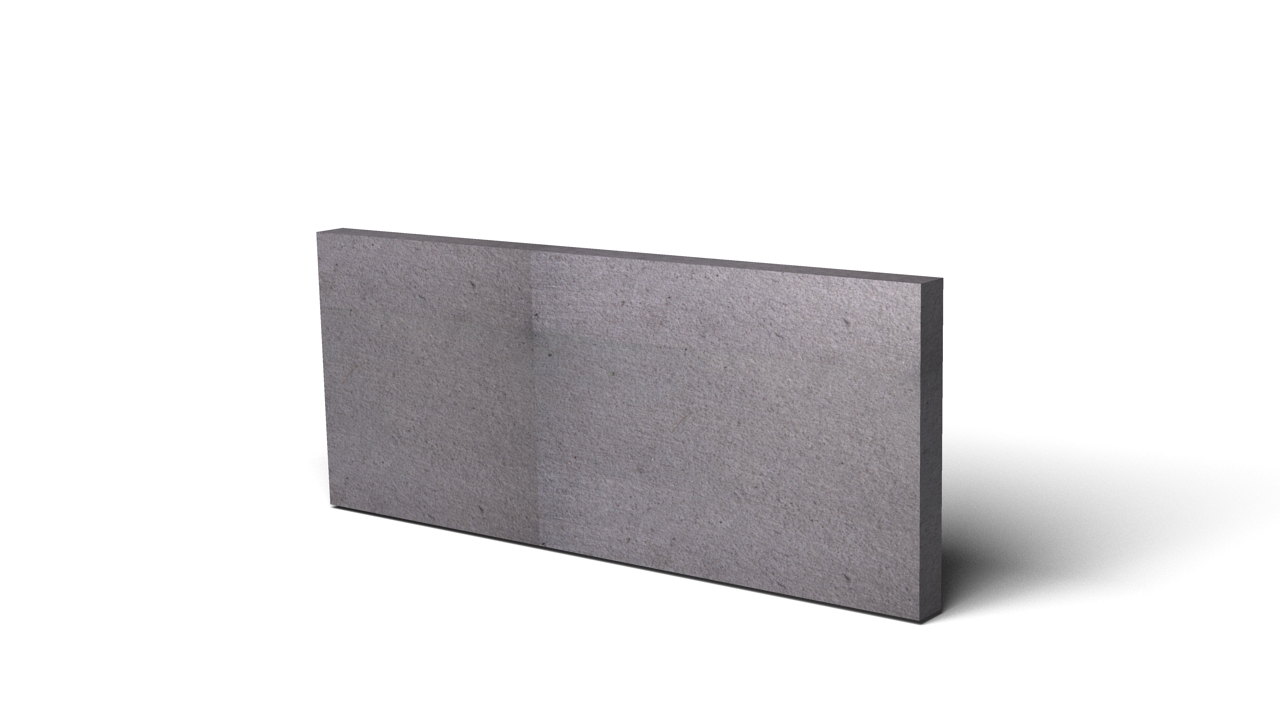

- Timber can be completely eliminated with the use of our plastic ply options

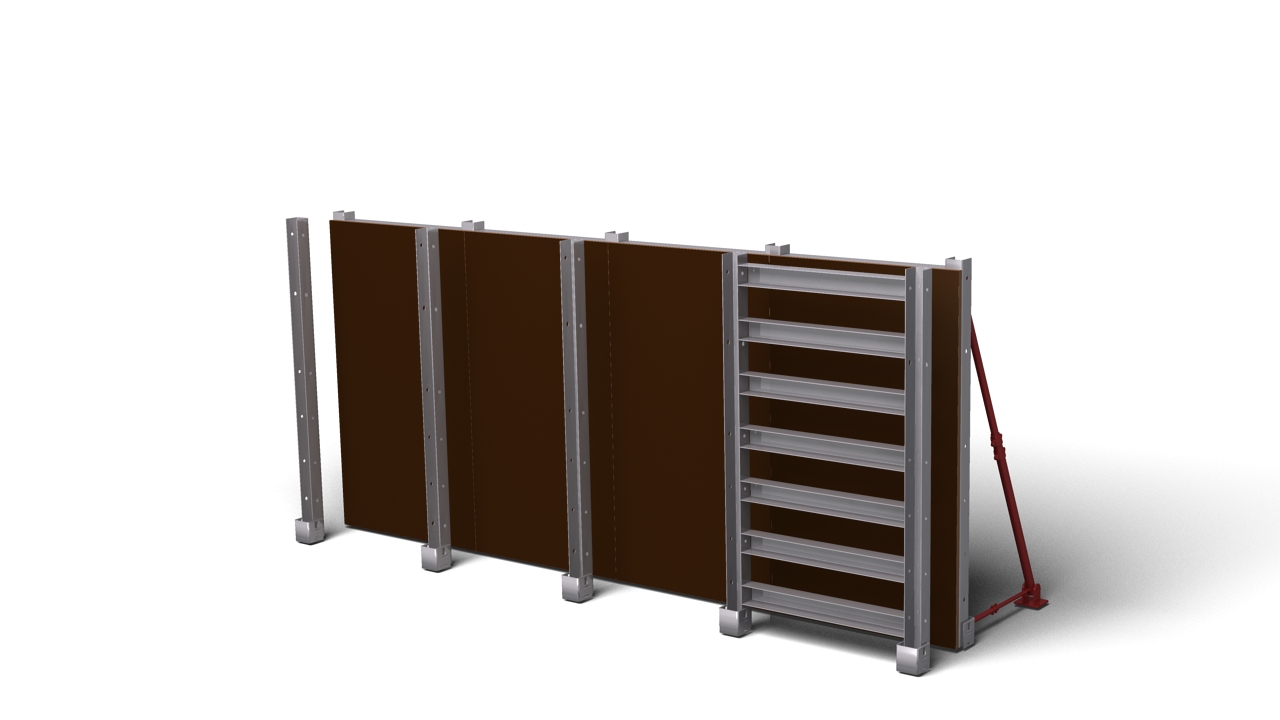

- The Fast-Form™ wall formwork system offer less make up, no de-nailing, lightweight and an easy to use system that is much faster than traditional methods and very simple to use, with low skill levels required

- The Fast-Form™ system can be used for hand fit up to 6.4m high, the same components can also be used for crane lifted large panels and also for radius wall formwork as well as column formwork, making it the most flexible system on the market

- With the Fast-Form™ system you get the benefit of a lightweight hand fit formwork system and the speed of a large panel systems with the finish of a timber system as our system is faced with plywood with no joints!

- Fair face finishes are easily achieved using the Fast-Form™ wall formwork system, we offer the best finish on the market with an F4 finish

Safer

- When timber wall formwork is used, where are the structural calculations? How does the risk assessment cover there being no handrail or access? The simple answer is timber does not offer these and in real terms it is an unsafe method of working in most applications, the Fast-Form™system eliminates all these problems

- The Fast-Form™ product range helps you meet manual handling regulations with no part more than 25kg

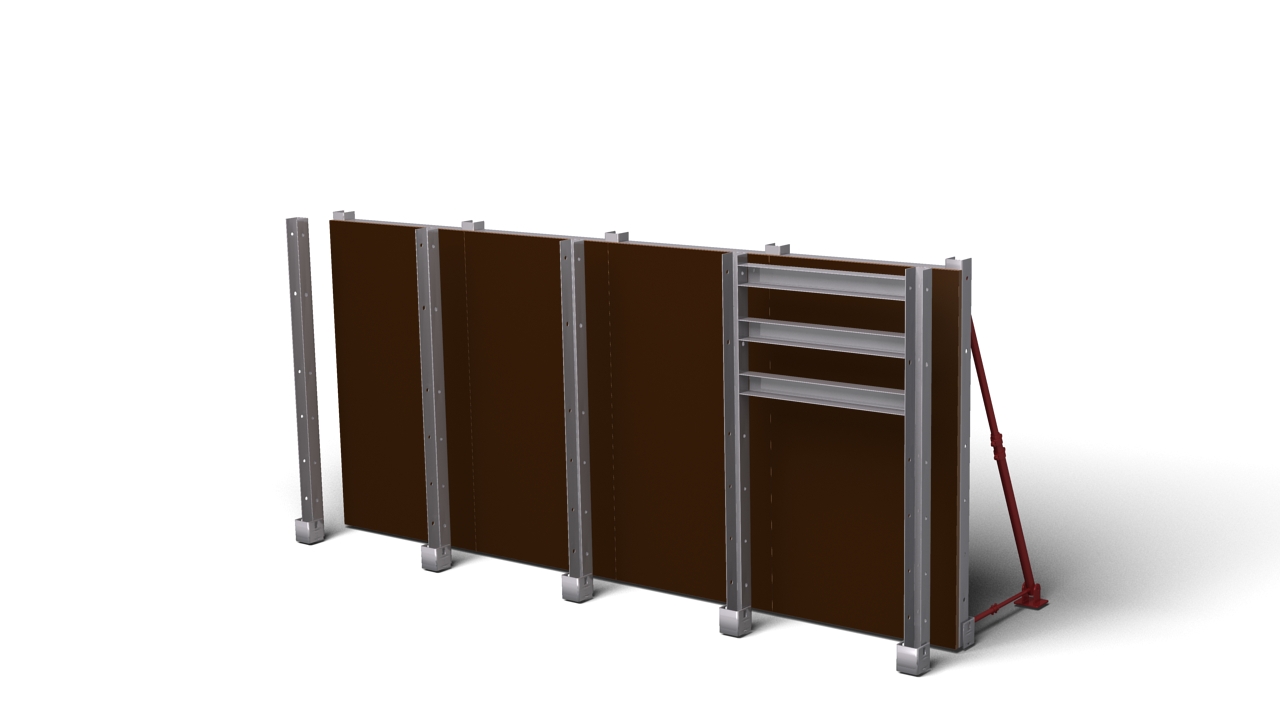

- Need handrails or access platforms? With the Fast-Form™ wall formwork system, they are easily attached and as they are part of our formwork system you don’t need a scaffolder to erect them which is an additional cost saving

- The Fast-Form™ wall formwork system comes with structural calculations and full colour 3D drawings and Temporary Works included

Greener

- Fast-Form™ wall formwork system can not only reduce timber usage, but with new plastic ply’s it can totally eliminate timber usage with fully recyclable materials that are much stronger and safer than timber-based products

- The Fast-Form™system has little or no timber wastage and 100% fully recyclable materials, greatly reduced carbon emissions from not only our wall formwork system but also reduced emissions from deliveries

- The Fast-Form™ system is the Greenest and Lowest Carbon system on the market

- On every job you can be issued with Carbon Saving Certificate that tells you how much carbon you saved using the Fast-Form™ wall formwork system vs other methods you could have used

Sustainable

- The Fast-Form™ formwork system has a 25 year plus lifespan and is made from 100% fully recyclable materials

- The Fast-Form™ wall formwork systems reduces timber use and so contributes to a sustainable solution that also reduces carbon use

Wall Formwork Advantages

Free design service, full structural calculations & 3D temporary works drawings are included.

Unlike other wall formwork systems, Fast-Form has no unsightly joints so is ideal for fair face finishes. The same components can also be used for straight or radius walls and columns. Our system comes in a range of sizes and widths which are quick and easy to assemble. The unique way our wall formwork system is assembled means that we can add or move pieces to accommodate for pipes/openings or to strengthen the system for single sided pours with no A-Frames!

A real alternative to timber systems with the best finish on the market, pour heights from 1.2m to over 6.4m, save time money and reduce your Carbon Footprint with our wall formwork system.